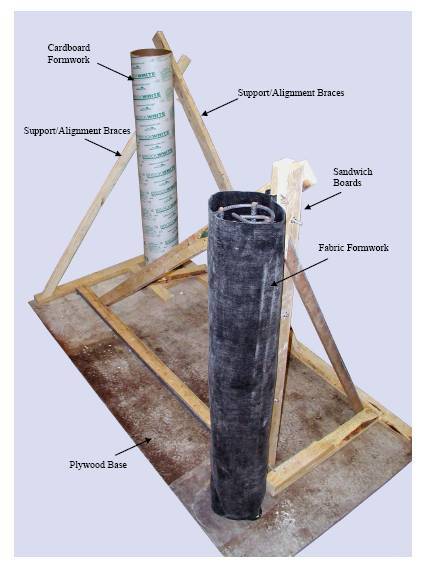

Table of Contents

Column Tests

In order to evaluate the effect of fabric formwork on structural behaviour of a column, full size fabric-formed and conventionally formed reinforced concrete columns were de-signed and tested to failure under concentric axial load. The variables in these tests were two types of formwork; permeable fabric versus cardboard and two types of concrete; Flyash concrete and normal concrete. The fabric of choice was Geotex 315ST due to its better surface finish.

Column Specifications and Design

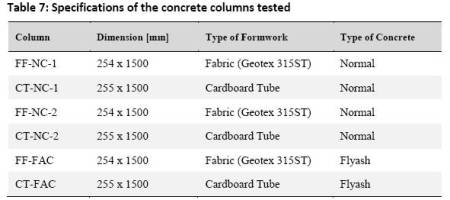

A total of six column specimens were tested to failure by applying a concentric axial load. Table 7 lists the specifications of the columns tested. FF stands for fabric formed columns, CT for cardboard tube formwork, NC for normal concrete and, FAC for flyash concrete. The design of the columns was limited by the capabilities of the available test-ing equipment. The detailed design of the column can be found in Appendix D.

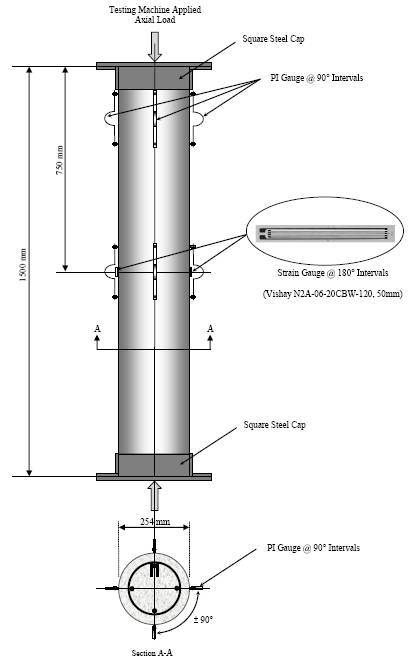

All columns had 254 mm radius and the column height was limited to 1500 mm. Based on calculations, four 15M bars were considered as the longitudinal bars, tie size was se-lected as 10M and tie spacing(s) was calculated as 250 mm (center to centre) and tie hooks, were set as 135 degrees. Arrangement and configuration of the reinforcement in the column has been shown in Figure 42.

The reason for repeated normal concrete specimen in Table 7 is the fact that the first try to form fabric formed column FF-NC-1 was not entirely successful. The column formed in a bulgy shape and there was a concern that the shape will affect the test results. A second column (FF-NC-2) with a corrected formwork was cast to provide a straight column for testing.

Column Casting

Formwork

Two types of formwork were used; Cardboard tubes and Geotex 315ST. 254 mm (10 in.) inside diameter cardboard column formwork was employed because it is a widely used conventional formwork in today’s North American construction industry .The cardboard forms used did not come with a non-absorbent plastic inside layer and therefore provided some water absorption from the fresh concrete.

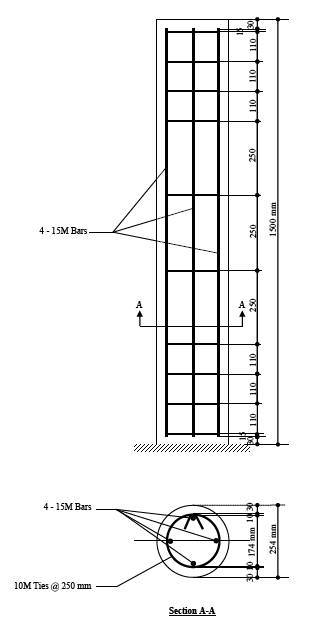

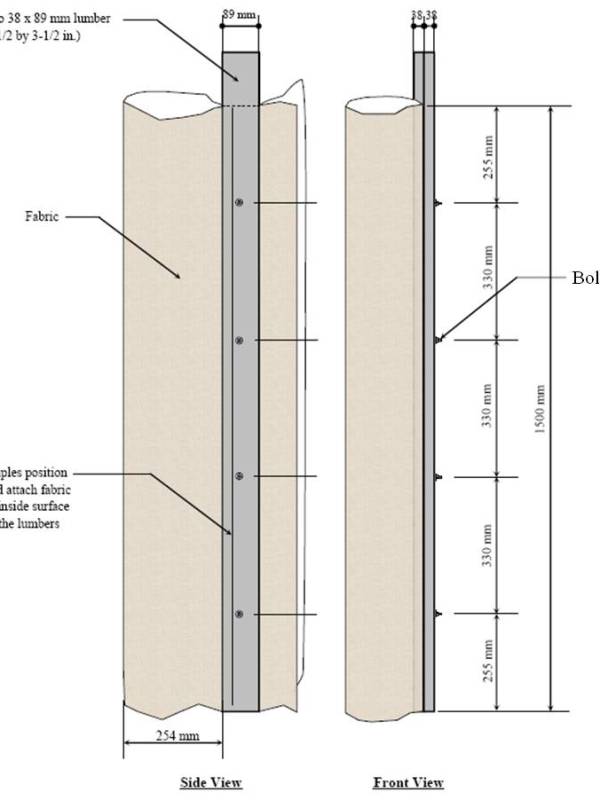

From the available fabric types Geotex 315ST was selected because it provides a better concrete finish. Both the control cardboard and fabric formed columns were cast simultaneously using the same concrete batch. The columns were cast using normal concrete and flyash concrete. Total of 6 columns were cast. As shown in Figure 43, the formwork was essentially the same as that used to cast the earlier cylinder specimens. The formwork was made of a single, rectangular, piece of fabric sandwiched between two vertical pieces of 38 x 89 mm lumber (2” by 4”). The fabric was first fitted to create the proper diameter and stapled to the lumber pieces.

After that, the wooden pieces were bolted together in four locations along the length of the formwork to make the closure of the formwork as a cylindrical vessel. Figure 44 shows the finished formwork set up for both cardboard and fabric formworks. Both formworks were supported in a vertical position by diagonal braces in two directions for lateral support. Plastic spacers (PVC chairs) were installed beneath the reinforcement cages in order to create a 30 mm space between the longitudinal bars and ties and the bottom of the columns. The cages were centered and then fixed to the wood floor using handmade aluminum braces in order to avoid possible movements of the reinforcement cage during the casting as shown in Figure 45.

«fs medium>The cover distance between both fabric and cardboard formworks was maintained by using plastic wheel spacers on the longitudinal bars. These spacers were also used to keep the reinforcement cage in the centre of the formwork during casting as shown in Figure 46.</fs>

Concrete

For these tests commercial 25 MPa concrete was ordered from a local ready mix concrete plant and delivered to the laboratory. An aggregate size of 5 to 20 mm, a slump of 90 mm, and an air content of 5 to 8% was specified.

When the concrete was delivered, the slump value was measured and fifteen 101 by 203 mm (4 by 8 in.) PVC control compressive strength test specimens were cast. Fresh concrete was transferred by hand directly from the truck mixer’s discharge chute to buckets and then into the forms as demonstrated in Figure 47. Each specimen was vibrated both inside and outside, using a portable electric internal vibrator at 5 to 15 second intervals. In case of fabric formwork, hand tapping the mold wall was also used to vibrate the concrete and help the bleeding of the air bubbles and extra water from the concrete. All columns and companion cylinders were cured in the same manner. Forms were stripped after one day, after which the columns, as well as the control samples were cured for another 3 days using wet burlap and plastic sheets as vapour barrier cover. Unlike in the cardboard formed columns, no sign of color variation was observed in fabric formed columns. No imperfections such as bug holes or the appearance of large aggregates were seen on the fabric-formed concrete surface. Such column could be easily used as exposed concrete structural members with no necessity for expensive patch ups, epoxy coatings or paintings or architectural veneers.

Test Setup and Instrumentation

Cured, ready-to-test columns were instrumented at mid-height and top end to measure the longitudinal and circumferential strains under the axial load. To measure circumferential strains, two strain gauges were installed on mid-height of each column, 750 mm from the top end with a 180 degree interval. The concrete surface was first scrubbed with a grinder before the installation of the strain gauges. Voids were then filled with epoxy. After about one hour, extra epoxy was removed by sanding the surface down. Strain gauges were then attached to the smooth void-free concrete surface using adhesive. Strain gauges were tested for correct resistance after installation using a volt meter. Wires were soldered to the strain gauges and then covered with a protective film of acrylic coating to protect them from possible damage before testing. Except the first two columns (FF-NC-1 and CT-NC-1) which had pi-gauges only on mid-height, a total of eight pi-gauges were in-stalled on each column. Four pi-gauges were placed on mid-height and four at the top end of each column to measure the displacement over the initial 200 mm length of the pi-gauges as shown in Figure 48. A Data Acquisition System (DAQ) was used to record the information gathered from 11 channels coming from the column instrumentations and testing machine (8 channels for the pi-gauges, 2 channels for the strain gauges and one channel for the load applied to the columns by the machine). Strain and pi-gauges were all tested for proper resistance and calibration just before every test session.

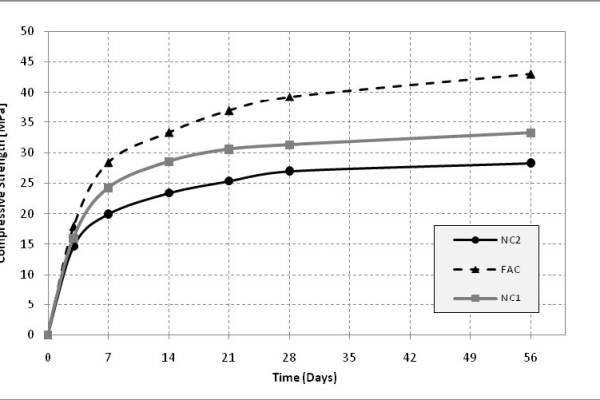

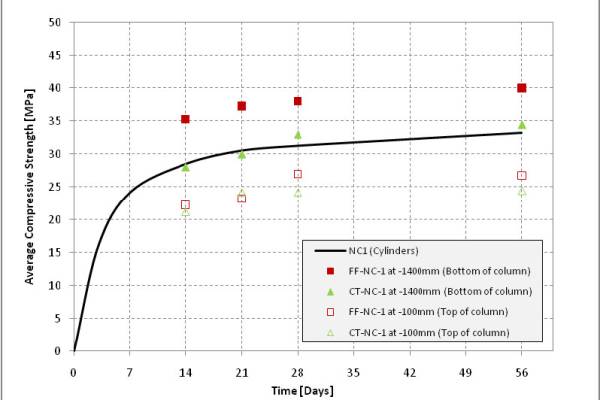

Companion Control Cylinders

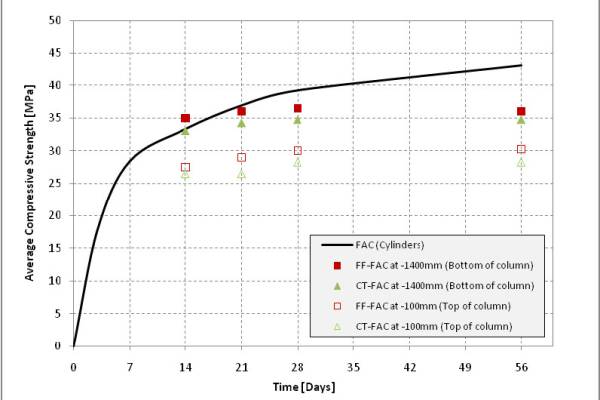

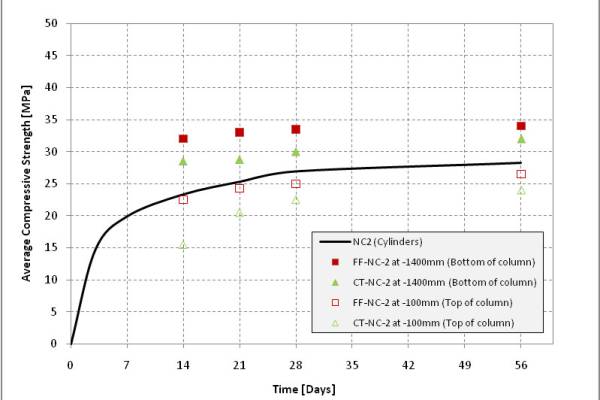

A compression testing machine was used to test the companion 101 by 203 mm (4 by 8 in.) concrete cylinders at the ages of 3, 7, 14, 28 and 56 days. All cured columns and the concrete cylinders were taken out of their molds simultaneously and were kept in the laboratory till testing. Figure 49 provides the data concluded from the cylinder compression tests. Both batches were specified to reach compressive strength of 25 MPa at 28 days but as the results show, the flyash concrete gained more compressive strength compared to the normal concrete. As seen in Figure 49, average compressive strength of the flyash sample at 28 days was measured as 39.2 MPa while the normal concrete specimens had average compression strength of 27 and 28.30 MPa. The actual compressive strength in both concretes was used to estimate the actual maximum axial load capacity of the columns.

Schmidt Hammer Tests

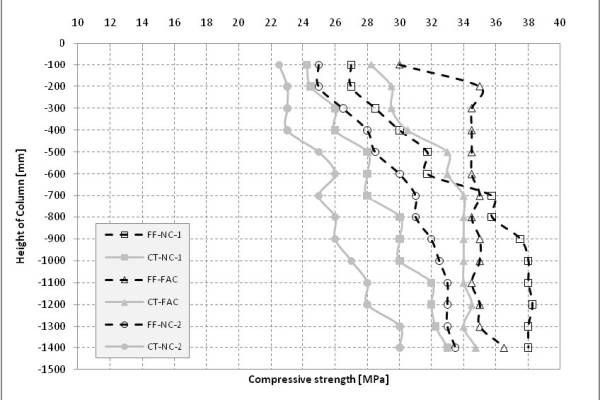

A rebound test was also used as a non destructive method to study the strength of the hardened concrete along their lengths. A Schmidt concrete test hammer (Proceq N/NR) was used in this research study. A grid of four vertical lines and 14 circumferential lines were drawn on the column surfaces. The grid lines provided locations to use the hammer at 14, 21, 28 and 56 days. Based on the manufacturer’s manual, a Schmidt hammer may be used to evaluate the pressure resistance of an equivalent cylinder between 14 - 56 days [1].

Instructions for preparation of the concrete surface were carefully followed before and during the use of the hammer. Each assigned point was tested for 8 impact readings. Following the manufacturer’s manual, the impact points were spaced at least 20 mm apart. The mean value of the 8 rebound values (R) was then calculated. Conversion curves were used to find the corresponding compressive strength of the average R values. For comparison purposes, only 28 day readings are provided in Figure 50. Charts showing the change in compressive strength along the height of the column for all columns have been provided in Appendix C.

As seen in the chart, all columns formed with fabric showed more surface strength than those formed with cardboard. When normal concrete is used, the difference between the compressive strength of the specimens cast in cardboard versus fabric formwork at the bottom of the column is between 12 and 15%. The difference between the formworks when using flyash concrete has minimal significance (5% difference). This is an indication of flyash particles possibly clogging fabric pores and therefore, reducing the amount of water bleeding and eventually resulting in less increase in compressive strength. In addition, regardless of the formwork type and referring to the results obtained from Schmidt hammer tests, the top end of the columns always proved to be weaker than other sections of the column. A phenomenon that appeared in both cardboard and fabric formed columns due to less compaction and less concrete density at top end of each column.

Compression strength test results from Schmidt hammer test have been compared to those from cylinder test for both normal and flyash concrete. As seen in Figures 51, 52 and 53, there are some fluctuations between the results obtained from Schmidt hammer and the PVC formed cylinders. The filled markers in the graph represent the bottom of the column, while the empty ones represent the top of the column.

As seen in Figure 51, compared to results from cylinder tests fabric formed column has gained an average of 21.8% extra strength at the bottom of the column while the bottom of the cardboard formed column shows almost the same results as the cylinders. At the top of the column, both cardboard and fabric formed columns showed an average of 28% less strength compared to the cylinder test results. As seen in Figure 52, cylinder test results for flyash concrete show more compressive strength than both top and bottom readings of the Schmidt hammer.

The difference between the readings of the Schmidt hammer at different ages stays constant but for some reason does not follow the strength indicated from cylinder tests. For the second set of normal concrete columns and cylinders, it can be seen in Figure 53 that compared to results from cylinder tests, fabric formed column has gained an average of 28% extra strength at the bottom of the column while cardboard formed column shows 14% difference. Schmidt hammer reading from the top of the columns shows 15% less compressive strength for cardboard formed columns and 6% less for fabric formed columns.

It is clear from the comparisons that for normal concrete the strength data from Schmidt hammer and from the cylinder test is comparable. Schmidt hammer is usually used to evaluate concrete strength of existing structures and it was shown in the previous figures that the strength is evaluated accurately. The method seems to be less accurate for the flyash concrete.

Column Compression Tests

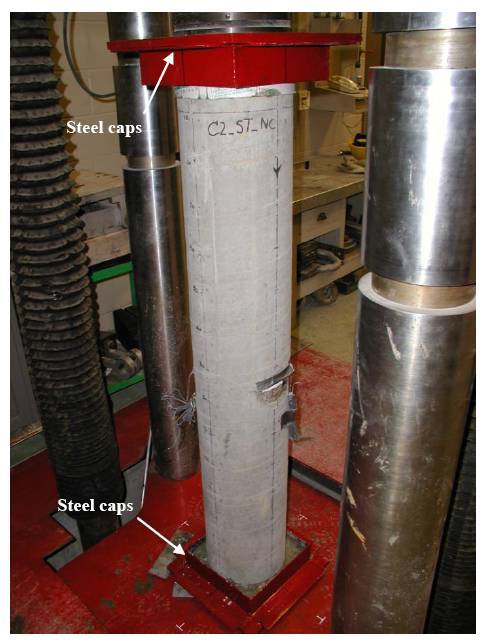

All columns were cured for at least 56 days before testing. Columns were oriented in vertical position in the testing machine and axial load was applied to the specimens with a load rate of 50 kN per minute until failure.

Two 280 by 280 mm (11 by 11 in.) custom made steel caps were made using a square base plate and four pieces of steel L-profiles welded vertically to the base plate as shown in Figure 54. Steel caps were made to confine the levelling grout on both ends of each column so that the axial load was evenly distributed over the column sections. No lateral supports were used to support the caps or columns.

Sika Grout 212 HP was used to level top and bottom of each column. Each column was first brought to the loading position, then lifted vertically using straps and cross head of the loading machine for about two feet. While the column was hung in the air, the steel cap was filled with 10-20 mm of the grout mixture.

The column was then slowly brought down to sit in the centre of the cap. After levelling the columns in a vertical position, specimen was left in place for 48 hours prior to testing day to let the grout gain its proper strength. To cap the top end of the column, a 75 mm circular cardboard mold was cut and used as a collar to retain the fresh grout in place when grouting the top end. First the collar was installed on top of the column, leaving only small room for the levelling grout. Then, grout mix was poured on top of the con-crete. Steel cap was immediately placed on the fresh grout and levelled. A slight engagement of the machine’s load piston also helped the cap being fixed in position until the grout set.

Due to the hand-made construction of the fabric molds, the columns cast by fabric formwork, did not have a completely uniform diameter along their lengths, making for a slight undulation along their sides. This slightly uneven surface did not allow the direct use of a carpenter’s level for alignment and vertical positioning. Once the columns were brought down to sit in the fresh grout inside the caps, they were aligned using two Theodolites and then fixed in place using the machine load piston. To achieve more accuracy in alignment when testing both types of the columns, they were pre-loaded to obtain some data readings and then using the data from the strain and pi-gauges, further adjustments were applied to centre the columns under the loading piston.

Test Results

Failure Patterns

In order to be able to better observe behaviour and the failure pattern of the columns, all tests were videotaped. The failure pattern of the columns was a factor to be investigated in this phase of the study. Based on observations of the two cardboard and two fabric-formed column tested, the failure of the cardboard formed column started with crushing on top and then spalling till failure. Cardboard-formed columns presented a typical gradual failure with no sign of brittleness, no longitudinal cracks and no flaking. On the other hand, fabric-formed columns started with crushing on top and development of longitudinal cracks at the same time along with spalling. Also, some flaking and relative sudden failure of outside surface was observed. Photographs of these column failures are shown in Figure 65 (page 82).

Compressive Strength

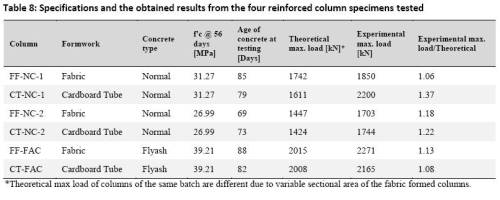

Compressive strength as given by the control cylinder tests at the age of 56 days was used to recalculate the theoretical expected maximum axial load of the steel reinforced column specimens. Table 8 provides a summary of the specifications of the tested columns and the obtained results. It can be noted that the formwork type had no bearing on the strength of either the normal or flyash concrete columns.

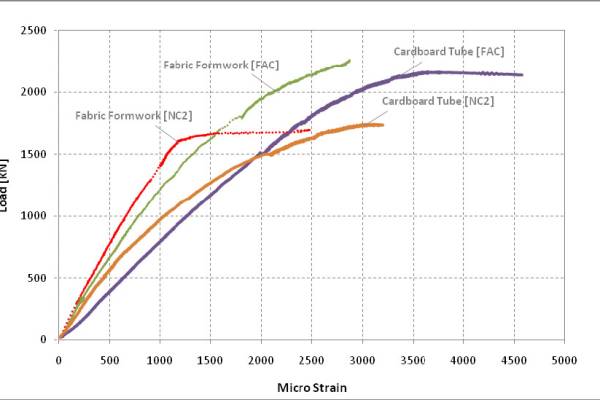

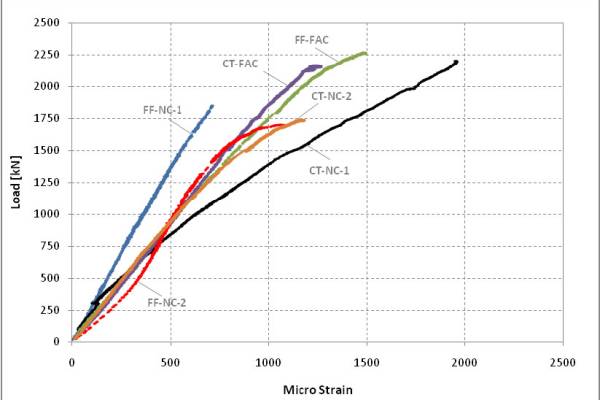

As seen in Table 8, the first two columns (FF-NC-1 and CT-NC-1), normal concrete columns formed with fabric and cardboard, withstood 1850 kN and 2200 kN of axial load, respectively. Maximum axial load of flyash specimen (FF-FAC and CT-FAC) was 2271 kN for fabric formed column and 2165 kN for cardboard formed column. As shown in Figure 55, for the last two columns (FF-NC-2 and CT-NC-2), normal concrete columns formed with fabric and cardboard carried 1703 kN and 1744 kN of axial load, respectively.

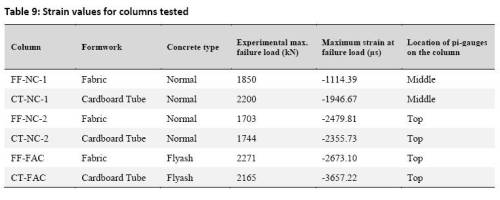

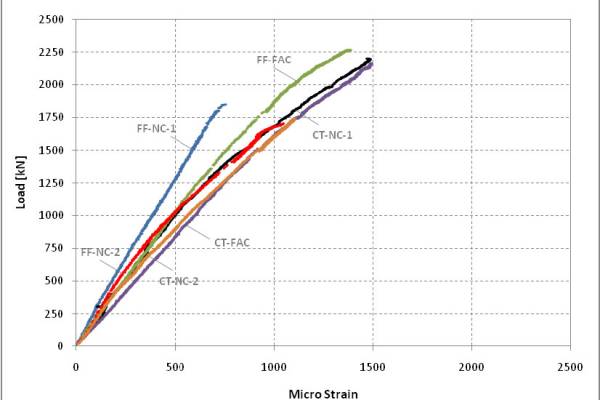

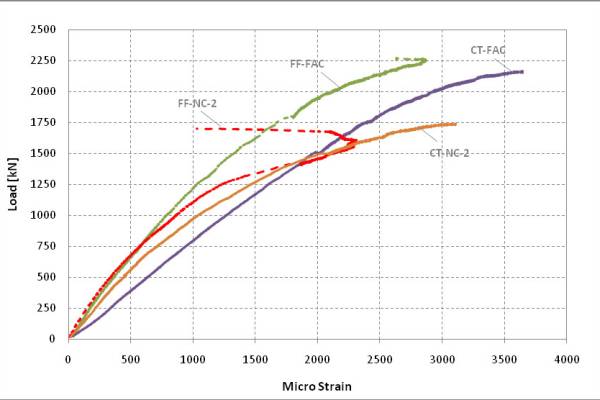

The first normal concrete fabric formed column (FF-NC-1) became bulgy and uneven due to improperly installed fabric. This made it more challenging to centre the sample in testing machine. This fabric formed column failed at 1850 kN that is 15.9% lower compared to the companion cardboard formed column CT-NC-1. For this reason, another set of two columns were cast using normal concrete (FF-NC-2 and CT-NC-2). The maximum strain values plotted in Figure 55 are provided in Table 9 for all the columns tested. Regardless of the location of the pi-gauges, these strain values are the highest recorded values in the concrete at the time of failure of the column.

The columns were instrumented to measure both longitudinal and circumferential strains. Available readings for individual columns at all pi-gauge locations are provided in Appendix E. Column FF-NC-1 and CT-NC-1 had instrumentation only in the mid-height section. The rest of the columns were instrumented both at the top and mid-height point of the column.

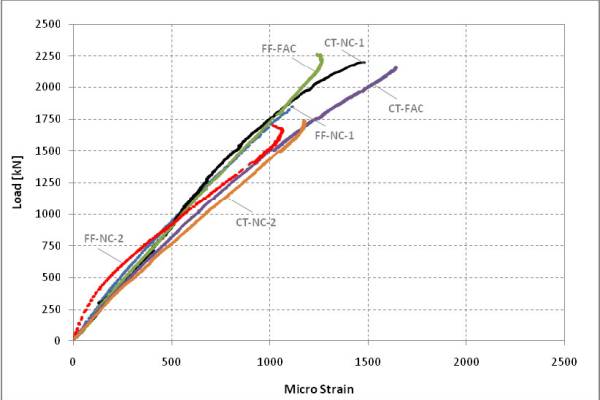

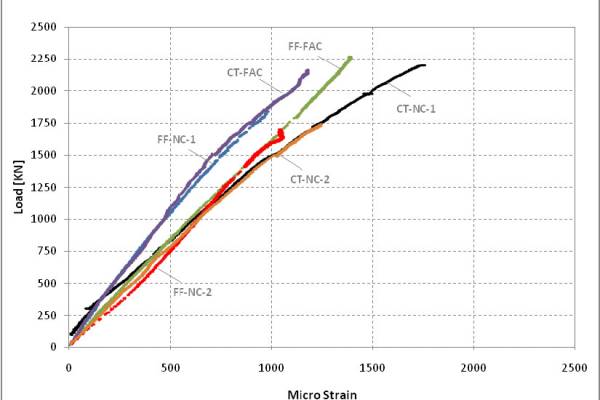

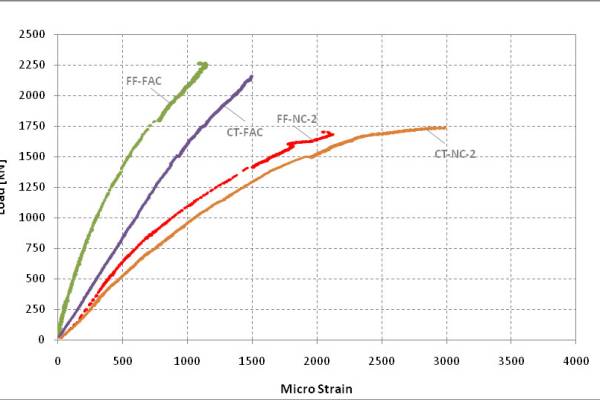

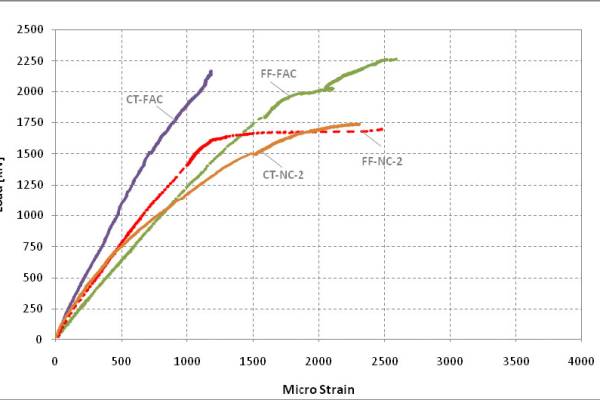

Figure 56 to 59 depict the strains in the middle, while Figures 60 to 63 depict the strains at the top of the column. Each figure represents one location either North, South, East of West and strains of that location in each column were plotted in the same graph for comparison.

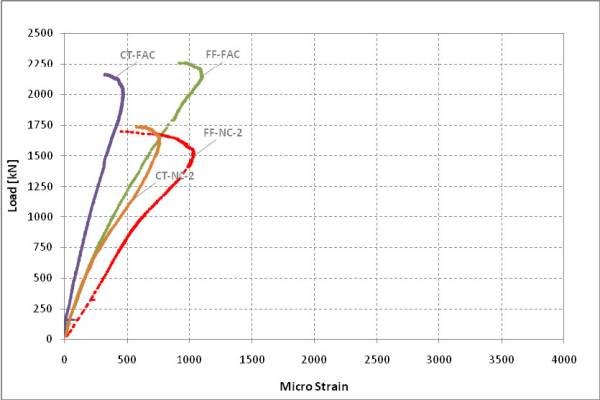

As seen in Figure 60 which represents the readings from North pi-gauges at the top of all columns, a trend of reverse strain close to the failure load is observed. This means that as columns were starting to crush at another location, the surrounding concrete was experiencing some tension. Figure 61 represents readings from South pi-gauges at the top of all columns. As seen in this figure, columns undergo much larger strain values as high as 3600 micro strain at the load of about 2150 kN in case of column CT-FAC. Strain values read from the south pi-gauge of column FF-NC-2 change direction from compression to tension close to the failure load. This has been caused by the uneven failure of the column at top. As seen in Figure 64, the opposite side of the column across from the south pi-gauge has failed in compression and caused some tension in south-top-zone of the column. Figure 62 which represents the readings from West pi-gauges at the top of all columns shows the highest strain in column CT-NC-2 as 3000 micro strain at the corresponding load of 1750 kN. A similar trend is observed in Figure 63 from the values taken from top-East pi-gauges. Column FF-FAC carries 2700 micro strain at the load of 2250 kN. As seen in all top pi-gauge curves, except column CT-NC-2, regardless of the form-work type, flyash concrete experienced more strain than normal concrete. As seen in Figure 65, all six columns failed at the top. This type of failure in columns has been documented before in research conducted by Bazant and Kwon [2] which found that regardless of the cross sectional size of the column, the fracture mechanism stayed the same. The reason for the top end failure is that the top end of a vertically cast member will always have less compressive strength than the lower parts of the member, due to increased pressure and compaction towards the bottom of the mold [3]. This holds true regardless of the formwork used.

Flaking and surface concrete delamination observed in the failure of both fabric-formed columns also confirms that the surface of the concrete cast in fabric formwork was more brittle than concrete cast in conventional formwork. The change in Poisson’s ratio was also studied when these columns were tested. The value was derived from dividing the average value of the data from two circumferential strain gauges placed at 180° apart from one another, by their corresponding axial pi-gauges. Both flyash and normal concrete fabric formed columns, proved to have lower Poisson’s ratio value which is another indication of brittleness and less surface deformation in the fabric-formed specimens. It is necessary to mention that it is nearly impossible to form a perfectly straight column using handmade fabric column formwork, so very small values of eccentricity in loading condition may occur. Since small values of the eccentricity do not create large moment values at end portion of the columns, the effects of small eccentricities can be neglected [2].

In each concrete type, both fabric-formed columns withstood the same axial load level as the cardboard formwork control samples. All samples failed at the top portion. At the extreme top portion of a concrete column, a permeable fabric mold does not loose appreciably more water than a conventional formwork or a cardboard tube. Therefore, in columns cast with the similar type of concrete, regardless of formwork material, strength of the concrete at top zone always remains the same and constitutes the area of weakest concrete in each column.

This test proved that use of a well designed permeable fabric formwork for casting steel reinforced concrete column is safe while it provides several advantages such as improved surface finish, lower material costs and the possibility of creating organic concrete forms with lower cost than conventional formworks. Concrete produced with fabric formwork is structurally capable of bearing the same loads as conventionally formed concrete.

Lessons Learned About Fabric Formwork

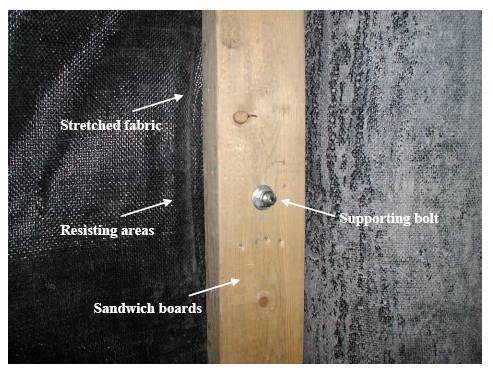

Our first attempt of casting a concrete column using fabric formwork was not quite successful. The column was bulgy at some points and it did not have constant diameter along its length while cardboard molds that are industrially manufactured are perfectly symmetrical tubes and form perfectly symmetrical columns. The reason for this problem was that the fabric was sandwiched between the boards using bolts and when the concrete was poured inside the mold, the hoop tension created by the liquid concrete pulled the fabric out between the bolts (Figure 66). Areas supported by bolts resisted the pressure while parts away from bolts deformed creating bulges along the length of the hardened concrete column, as shown in Figure 67.

To avoid such problem, another formwork was built but this time, the fabric was stapled to the sandwich boards along the length of the fabric. Staples were applied on a straight line, only a few millimetres apart from each other (though less staples would be probably also sufficient), providing a stitch line from top to bottom of the formwork. Orientation of the stitch line can be seen in Figure 43. Stapling provided an even distribution of the hoop forces along the height of the formwork and resulted in a uniform cylindrical geometry. The variation in diameter of the column along its length was dramatically reduced as demonstrated in Figure 68.

When casting concrete columns in fabric formwork, extra attention must be paid to the initial concrete distribution at the bottom of the mold. In order to avoid problems, first scoops of the concrete must be vibrated by hand from outside to make sure fresh concrete has been evenly distributed inside the mold and the bottom of the fabric formwork tube does not rise up during this initial concrete placement. A video showing commercial practice for casting cylindrical fabric formed columns can be seen on the Fab-form website (http://www.fab-form.com/products/fasttube/fasttube_video.html).

See Also

[1] Comments by RPS on Discussion page for an alternative way to secure the column fabric, Figure 43.

<fs medium>[2] Place text here.

References

[1] Proceq. Concrete Test Hammer Manual. 2002. http://www.papworths.com.au/docs/2/Manuals/Schmidt%20Hammer%20Type%20N%20L%20NR%20LR%20Manual.pdf (accessed June 16, 2009).

[2] Bazant, Z. P., and Kwon, Y. W. “Failure of Slender and Stocky Reinforced Concrete Columns.” Materials and Structures, 1994: Vol. 27, 79-90.

[3] Maynard, D. P., and Davis, S. G. “The Strength of In-situ Concrete.” The Structural Engineer, 1974: Vol. 52, 369-374.