This is an old revision of the document!

Table of Contents

Introduction

Fabric formwork, as a new concrete forming technique, provides technical advantages and new freedom to the architects, engineers and concrete formwork industry. Fabric-formed concrete members are easy to form, immaculate in finish (Figure 1), organic in form, and inexpensive to produce.

The surface finish of concrete formed in wood, steel or plastic molds generally has imperfections, often requiring further touch ups and costly treatments (Figure 2). Lumber and plywood used for conventional concrete forming are often used a few times and then sent to the landfill site. Creating curves and organic forms using conventional concrete forming is also time consuming, expensive and labour and material intensive. Fabric formwork can use a flexible woven nylon, polyolefin, polyester, polypropylene, polyamide, or polyethylene membrane instead of rigid conventional forms or panels [1]. When fresh concrete is poured inside this membrane the fabric mold deflects into a repertoire of precise tension geometries.

Fabric formworks can be used to form columns, walls, beams, slabs and panels in both precast and in-situ construction. Fabric formwork can be simply built by construction connections and joints or can be sewn into any form, size, or shape on the job site or in the plant [2]. Fabric formwork is easy to use and build, very light and easy to transport, inexpensive as 1/10th of the cost of the conventional formwork, reusable and therefore, environmentally friendly [3]. To provide a comparison base between the techniques, a cost analysis has been provided in Appendix A.

Although woven and non-woven fabric formworks are commercially available the effects of permeable fabrics on the quality of concrete has not been thoroughly investigated. This research is an experimental investigation of the change in concrete properties due to permeable fabric formwork using common and commercially available geotextile fabrics. Concrete close to the surface of a conventional formwork always has a higher water cement ratio than the core concrete [4]. Woven geotextiles used as forming membrane in fabric formwork technique have very small pores letting air bubbles and excess mix water bleed out, leaving a cement-rich paste at the surface of the concrete. This filtering action reduces the water cement ratio of the concrete at the surface zone and produces immaculate finishes unknown to other conventional methods of concrete construction. The low surface water/cement ratio in turn, makes the concrete more waterproof and causes less shrinkage and fewer cracks in the long term [4].

Background and History

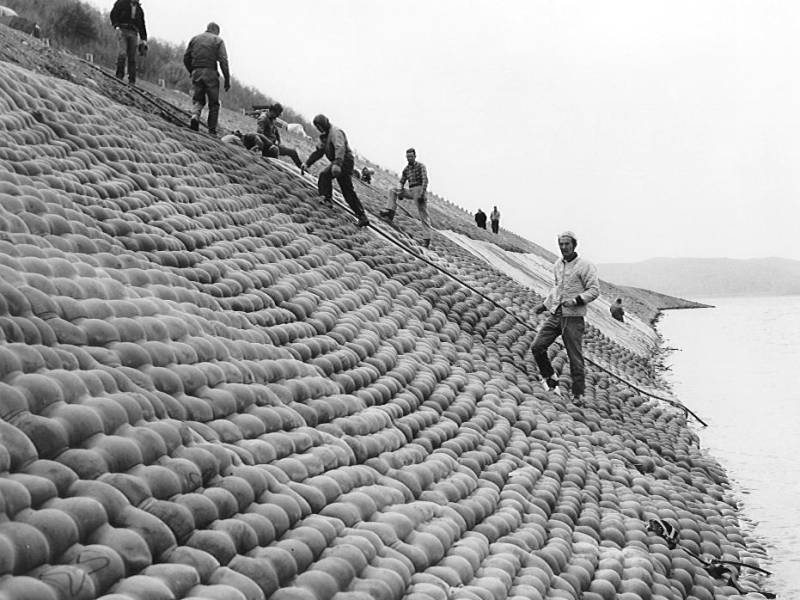

<align justify>The first fabric formwork patents appear in the late 19th century. The first architectural and industrial use of fabric formwork was introduced in 1950s by Félix Candela who was famous for construction of reinforced concrete shells (Figure 3). Burlap fabric stretched over timber arches was the simple formwork he used to form ribbed, parabolic shells [5]. In the 1970’s Spanish architect Miguel Fisac successfully used plastic sheets as formwork for textured wall panels. His technique was used to form architectural wall panels (Figure 4) in several buildings [6]. Further practical applications occurred in the mid 1960’s with the introduction of fabric formwork for erosion control and pond liners (Figure 5). The efforts of E.W. Bindhoff [7], B.A. Lamberton [8], and others led to the first sustained commercial applications of fabric formworks.</align>

<align justify>In the late 1980’s a Japanese architect named Kenzo Unno, invented a system for fabric-shuttered walls [9]. Around the same time, Richard Fearn, a builder and businessman in Canada, invented a number of fabric formwork techniques which developed into a series of foundation footing and column formwork products (www.fab-form.com 2009).</align>

<align justify>Also beginning in the mid 1980’s, Mark West, architecture professor at the University of Manitoba invented a series of techniques for constructing fabric-formed walls, beams, columns, slabs, and panels. Research in the area of fabric formwork construction have been carried out at the Architectural Structures and Technology (C.A.S.T.) at the University of Manitoba, the first research centre dedicated to fabric formwork technology and education [10].</align>

<align justify>The first international conference on fabric formwork was held in summer 2008 in Winnipeg, Canada. At this conference the International Society of Fabric Forming (ISOFF) was formed. ISOFF has been created to communicate the work of researchers in fabric forming to manufacturers and concrete formwork industry [11].</align>

Previous Studies Using Permeable Rigid Formwork

<align justify>In the civil engineering industry, two types of permeable formwork have been introduced, studied and used before. One technique is called permeable rigid formworks or drainage formliners and the other one is fabric formwork which is not a rigid mold.</align>

<align justify>Permeable rigid formworks or drainage formliners have an absorptive or permeable layer inside conventional rigid formwork (often a woven or nonwoven fabric) filtering air and water from the concrete at the mold surface. The surface of the concrete formed in permeable formworks is denser and stronger and has fewer imperfections than the same concrete formed in a conventional formwork without a drainage formliner [4]. Generally, with a conventional formwork, surface zone concrete has always more water than the concrete in the centre of the material mass. This high water-cement ratio at the surface, results in weaker and more permeable concrete [12]. The bleeding phenomenon from a drainage formliner creates a filtering action which in turn, increases the concentration of fine aggregates close to the surface of concrete giving it a very fine finish and increased impermeability. X-ray radiographs have shown 10 percent higher cement to fine aggregate ratio in surface zone concrete cast in fabric formwork [13]. Marosszeky reported a 70 percent increase in the strength of the surface concrete cast in permeable but rigid formworks as well as improved resistance to chloride ion penetration and a 100 percent increase in pull-off strength [14].</align>

Previous Studies Using Fabric Formwork

<align justify>Fabric formwork technique takes advantage of a nonrigid woven or non-woven fabric to form concrete. Bleeding characteristics of the available fabrics allow the extra water and air bubbles to bleed out from the formwork and reduce water-cement ratio at the surface of the concrete member. Koerner and Welsh, reported a reduction in water-cement ratio of fabric formed concrete mats (made of woven nylon) used to control erosion and waves from 0.63 - 0.61 range down to 0.39 with no actual test on change in concrete compressive strength [1].</align>

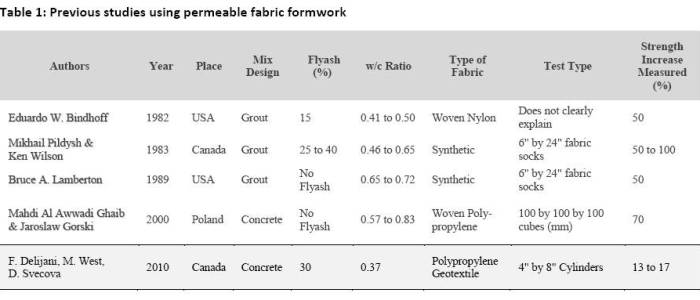

<align justify>As seen in Table 1, Bindhoff reported a 50 percent increase in cement grout compressive strength using the results from tests on cores from fabric formed pile jackets and companion specimens cast in conventional watertight molds [7]. Bindhoff et al. used flyash in order to increase the waterproofing properties of underwater concrete. The work of Pildysh and Wilson found 50 to 100 percent increase in compressive strength of concrete due to fabric formwork [15]. In their research, 152 by 305 mm (6 by 24 in.) hanging fabric socks were first vertically filled with grout under pressure and then a 152 by 305 mm (6 by 12 in.) test cylinder was cut out of the hardened mortar and compared to control conventionally formed samples. Pildysh and Wilson used 20 to 40 percent flyash was used in mortar mix design with only sand and no gravel.</align>

<align justify>Lamberton also showed a 50 percent increase in compressive strength in fabric formed concrete [8]. In these tests, 139 by 305 mm (5.5 by 30 in.) fabric socks were cast vertically under 69 kPa injection pressure and then 152 by 305 mm (6 by 12 in.) cylinders were cut from the middle section of the hardened specimen. 5 to 10 percent stretch in the fabric used was considered when the initial 5.5 inch sock diameter was selected. Cement mortar was used to cast fabric formed cylinders using Portland cement and sand without of gravel.</align>

<align justify>Ghaib and Gorski used four textile mattresses (made of woven polypropylene) filled with concrete mixes with different slump values [16]. [A total] of 232 samples of 100 mm cubes were cut out from the hardened concrete mattress by electric saw and then compared to a series of 100 mm cubes control samples. Analysis of the compression strength tests showed up to 70 percent increase in compressive strength at the age of 28 days. It was found that the compressive strength of the concrete cast in fabric was a function of the pore size of the fabric used. In general, the compressive strength of fabric-formed concrete decreased as the pore sizes increased more than 0.35×10-3 m.</align>

Objectives and Scope

<align justify>The present research study was designed to reevaluate the change in concrete properties due to fabric formwork and to evaluate the applicability of the ASTM standard for testing fabric formed cylinders.</align>

<align justify>The need for conducting such research became essential for several reasons: test methods used in former fabric formwork studies were not compatible with any specific standard testing method, all but one previous study used cement grout instead of concrete, and all previous studies used relatively high water cement ratio mix designs except Ghaib et al. [16]. Although Ghaib et al. used woven polypropylene fabric the specific type of fabric they used is unspecified [16].</align>

<align justify>Taking advantage of the work done in C.A.S.T. and years of using different types of available fabrics and geotextiles to form concrete, The Geotex 315ST geotextile (formerly named Propex 2006) was chosen for use in this research study. In full scale construction tests, Geotex 315ST showed good mechanical properties as a formwork fabric. It created a very good texture when exposed to cement mortar or fresh concrete. It is also one of the less expensive fabrics available among Geotex products. This geotextile is a woven “structural” fabric made of ultraviolet (UV) resistant polypropylene fibre with sufficiently high tensile strength in both warp (yarns running the length of the fabric) and weft (yarns running across the width of the fabric) weave directions.</align>

<align justify>Although mechanical properties and practical workability of Geotex 315ST were known to us, the change in overall quality of the concrete was undefined. The knowledge of change in concrete properties due to fabric formwork was limited to a few research studies available, claiming up to hundred percent increase in concrete’s compressive strength when cast in different types of fabrics [7]. The need for conducting such research became essential when the methods used in former fabric formwork studies were not compatible with any specific standard testing method. The scope of this project is limited to two types of Geotex geotextile fabric and two types of concrete; Normal concrete (NC) and flyash concrete (FAC).</align>

<align justify>There are no ASTM or Canadian standards for forming fabric formed laboratory test cylinders, but the type of mold used in this research study provides some basis for testing and comparing the quality of concrete cast in fabric molds. Compared to the “sock” technique [8] or the “mattress” technique [16] used in previous research testing, the test procedure proposed in this thesis is attempting to be close to conventional cylinder casting as recommended in ASTM C39/C39M-04a [17]. The method provides more practical comparisons for structural applications. Compressive strength of all cylindrical concrete specimens was determined on the basis of the standard test method [17].</align>

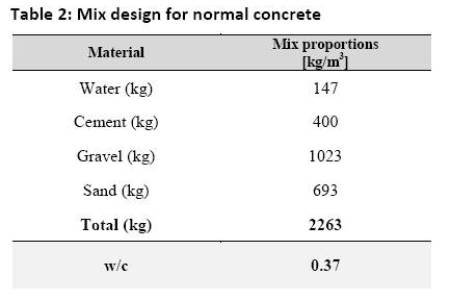

<align justify>The mix design in this study was selected in order to simulate an everyday use general concrete quality. Compressive strength of 30 MPa (at 28 days) was selected as the average strength range to satisfy the above mentioed condition. The mix design used in this research (Table 2) was adopted from Mindess et al. [18]. Expected average 28 days compressive strength was 30 MPa with the slump value between 75 and 100 mm. The properties of the material were as follows:</align>

- Cement: Type I (produced by Lafarge Canada)

- Fine aggregate (Sand): Average absorption capacity = 1.38% (as measured in the lab).

- Coarse aggregate: Maximum size = 19 mm (3/4 in.), river gravel (round corners), average absorption capacity = 1.25% (as measured in the lab).

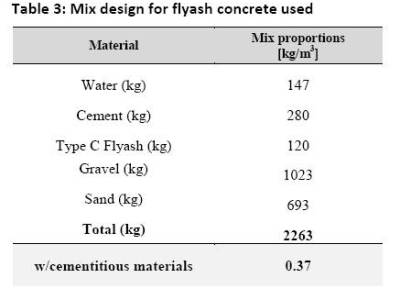

<align justify>Based on proportions expressed in Table 2, water-cement ratio in this mix design was found to be 0.37 which unlike former studies described in Table 1, is a relatively low. For flyash concrete, 30 percent of the cement in the ordinary concrete mix design was replaced with type C flyash (Table 3).</align>

See Also

References

[1] Koerner, Robert M., and Welsh, Joseph P. Construction and Geotechnical Engineering | Using Synthetic Fabrics. Somerser: John Wiley & Sons Inc., 1980.

[2] Abdelgader, Hakim, West, Mark and Gorski, Jaroslaw. “State-of-the-Art Report on Fabric Formwork.” International Conference on Construction and Building Technology 2008, Malaysia: ICCBT 2008, 2008. pp 93-106.

[3] West, Mark. “Fabric Formed Concrete Structures.” First International Conference on Concrete and Development. Tehran: Building and Housing Research Centre (Iran), 2001. 133-142.

[4] Malone, Philip G. Use of Permeable Formwork in Placing and Curing Concrete. Vicksburg: U.S. Army Engineer Research and Development Center, 1999.

[5] Lee, Daniel S. H. “Some Technical Aspects of the Use of Fabric Formwork.” In Fabric Formwork, by Alan Chandler and Remo Pedreschi, 77-83. London: RIBA Publishing, 2007.

[6] Soler, Francisco Arqués. Miguel Fisac. Spain: Ediciones Pronaos, 1996.

[7] Bindhoff, Eduardo W., and King, John C. “World’s Largest Installation of Fabric-Formed Pile Jackets.” Civil Engineering—ASCE, 1982: Vol. 52, No. 3: 68-70.

[8] Lamberton, Bruce A. “Fabric Formwork for Concrete.” Concrete International, 1989: December Issue: 58-67.

[9] Chandler, Alan. “Building Walls – A philosophy of.” Arq, 2004: vol. 8, 204-214.

[10] C.A.S.T. The Centre for Architectural Structures and Technology. 2008. http://www.umanitoba.ca/faculties/architecture/cast/ (accessed June 25, 2009).

[11] ISOFF. International Society of Fabric Forming. 2008. http://www.fabricforming.org/ (accessed July 10, 2009).

[12] Reddi, S. A. “Permeable Formwork for Impermeable Concrete.” Indian Concrete Journal, 1992: Vol. 66: 31-35.

[13] Cron, F. W. “Effect of Absorptive Form Liner on Surface Durability of Concrete.” Public Roads, 1970: 36(3), 53-59.

[14] Marosszeky, Marton, Chew, Michael, Arioka, Massi, and Peck, Phillip. “Textile Form Method to Improve Concrete Durability.” Concrete International (Building Research Centre, University of New South Wales), 1993: November Issue, 37-42.

[15] Pildysh, Mikhail, and Wilson, Ken. “Cooling Ponds Lined With Fabric-Formed Concrete.” Concrete International, 1983: September Issue.

[16] Ghaib, Mahdi Al Awwadi, and Gorski, Jaroslaw. “Mechanical Properties of Concrete Cast in Fabric Formworks.” Cement and Concrete Research, 2001: 31: 1459-1465.

[17] ASTM C39/C39M-04a, ASTM. “Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens.” In Annual Book of ASTM Standards, by ASTM, Vol. 04.02, 18-22. Easton: ASTM, 2004.

[18] Mindess, Sidney, Young, J. Francis, and Darwin, David. Concrete. Upper Saddle River: Prentice Hall, 2003.

[19] Arnardóttir, Halldóra, and Merina, Javier Sánchez. http://storiesofhouses.blogspot.com/. 2008. http://storiesofhouses.blogspot.com/2006/05/house-in-la-moraleja-madrid-by-miguel.html (accessed June 24, 2009).