This is an old revision of the document!

Table of Contents

Research Efforts

<align justify>Countries with schools of architecture and engineering with students conducting research include Belgium, Canada, Chile, Denmark, England, Germany, Mexico, the Netherlands, Scotland, and the United States. The most prolific research currently being conducted is under the direction of Professor Mark West, Director of the Centre for Architectural Structures and Technology (C.A.S.T.) at the University of Manitoba, Canada.</align>

Basic principles

<align justify>The author’s first introduction to flexible formwork came from reading an article by Professor West published in Concrete International [1]. A visit to C.A.S.T. in June of 2004 exposed the author to this most unique method of forming concrete members. Professor West and his architectural students at C.A.S.T. first began exploring the use of flexible formwork for precasting concrete wall panels in 2002 [2, 3].</align>

<align justify>The shape a wall panel could take was first explored using a plaster model with various interior support and perimeter boundary conditions (Figures 1-2). The cloth fabric, when draped over interior supports and secured at the perimeter, deforms as gravity forms the shape of the panel with the fluid plaster as shown in the completed plaster casts (Figure 3). Once a satisfactory design has been obtained, a full scale cast with concrete can be made.</align>

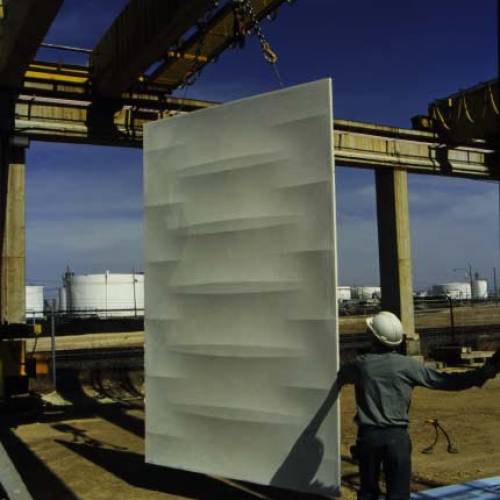

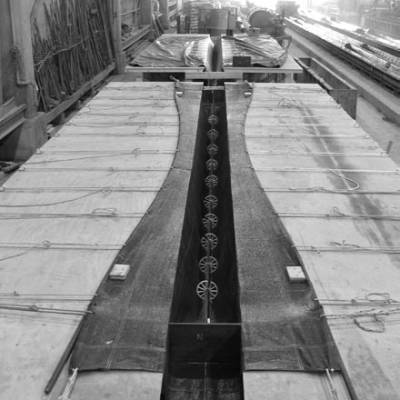

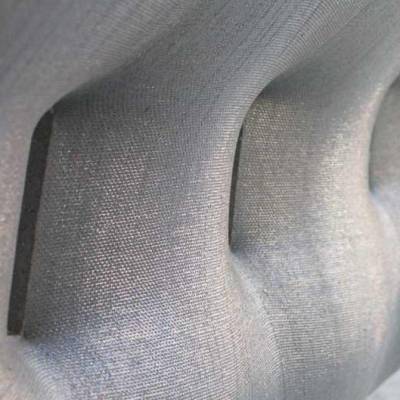

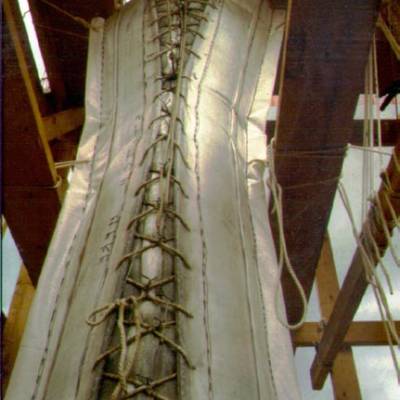

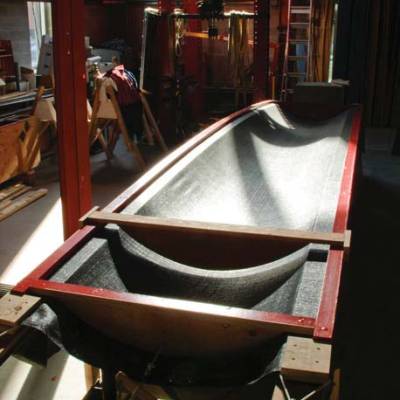

<align justify>The casting of a full scale panel using concrete requires finding a fabric capable of supporting the weight of the wet concrete. For this purpose, a geotextile fabric made of woven polypropylene fibers was utilized. Assorted interior supports were added to the formwork (Figure 4) and the flexible fabric material was pre tensioned at the perimeter (Figure 5). Depending upon the configuration of these interior support conditions, three dimensional funicular tension curves are produced in the fabric as it deformed under the weight of the wet concrete (Figure 6). Reinforcement added to the panel only served to hold it together and was not designed for any particular loading condition for the completed panel (Figures 7 and 8) Figure 9 shows the formwork used for the completed wall panel shown in Figure 10. Alternatively a completed wall panel may also serve as a form. The glass fiber reinforced concrete (GFRC) wall panel shown in Figure 11 was cast on the finshed surface of the panel Shown in Figure 10.</align>

Geotextile fabric as a formwork has a number of advantages including:

- The forming of very complex shapes.

- It is strong, lightweight, inexpensive, will not propagate a tear and is reusable.

- Less concrete and reinforcing are required leading to a conservation of materials.

- Filtering action of the fabric improves the surface finish and durability of the concrete member (Figures 8 and 12).

It also has several disadvantages including:

- Relaxation can occur due to the prestress forces in the membrane. There is the potential for creep in the geotextile material, which can be accelerated by an increase in temperature as might occur during hydration of the concrete as it cures.

- The concrete must be placed carefully and the fabric formwork must not be jostled while the concrete is in a plastic state.

We believe however, until new fabrics are developed the benefits of using geotextiles far outweighs any disadvantages.

Engineering Complex Forms

<align justify>The design of a fabric formed concrete panel may be approached in several ways. Each approach must take into account the panel’s anchor locations to the backup framing system. One approach might be to locate the anchor points based on the most efficient panel design. Another approach could be to locate the anchor points based on the most pleasing appearance the panel takes due to the deformed fabric shape, and still another could be to consider both efficiency and appearance as a basis for the anchor locations. </align>

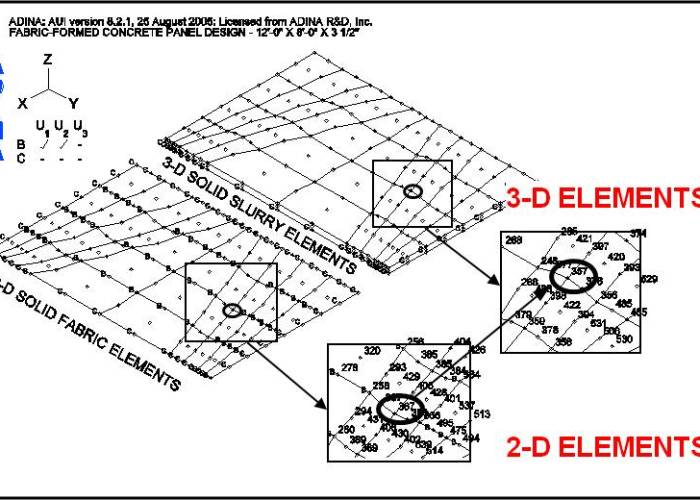

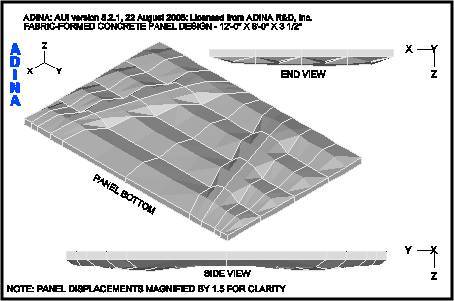

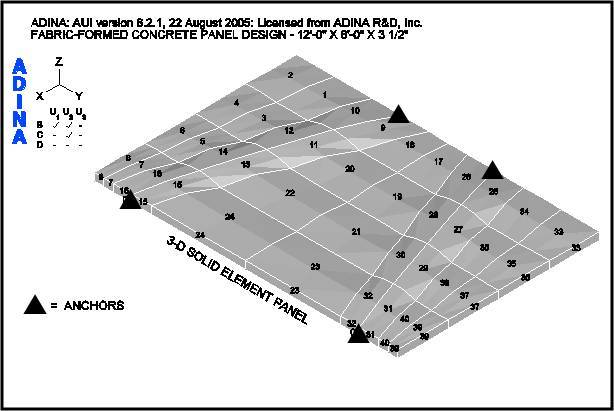

<align justify>How might a precast wall panel system, for example, be engineered? Straightforward methods of analysis and design are available for the traditionally cast concrete wall or floor panel. This is not so for the panel cast in a flexible fabric formwork. Shapes as complex as these require the use of finite element analysis (FEA) software. A procedure to “form-find” and analyze the complex panel shape is required (Figure 1). Prior to a thesis (2004) and a paper (2006) by the author to introduce a design procedure that allows one to design a fabric cast concrete panel, no design procedures or methods to predict the deflected shape of a fabric cast panel had been developed [4,5].</align>

<align justify>A four step procedure for analytically modeling a fabric formwork was developed employing the structural analysis program ADINA to analyze the formwork and the concrete panel cast in it [6]. The final panel form, function and performance of the fabric membrane and the reinforcement of the panel for design loads all add to the complexities of the panel’s analysis and design (Figures 2 and 3).</align>

<align justify>A precast fabric-formed concrete wall panel, poured flat in a bed, may be one of the simpler concrete members to analyze; but when it comes to other concrete member shapes, one thing is clear, the system will undoubtedly be very complex and a procedure using finite element methods will be required.</align>

See USA_Schmitz for current research efforts.

International Research

<align justify>While the list of countries conducting research into the use of fabric as a formwork for architectural works continues to grow, the research at C.A.S.T. has been the most innovative and pioneering effort the author has seen to date. Their research centers on the development of new technologies for forming concrete structural members using fabric formworks. They seek to:</align>

- Find new simple and efficient forming strategies using standard tools and fasteners for all the architectural applications mentioned above.

- Develop strategies that not only lead to an aesthetically pleasing structural form but that are efficient and sustainable as well.

- “…. make these new technologies available to both high and low capital building cultures.” (C.A.S.T. brochure)

<align justify>In addition to the fabric-formed precast concrete wall panels previously mentioned they have explored and continue to explore fabric-formed beams, trusses, columns, vaults and shotcrete thin-shell curtain wall systems.</align>

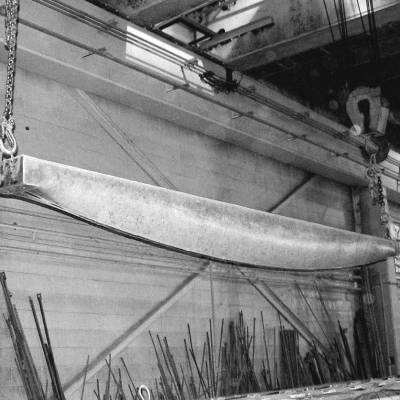

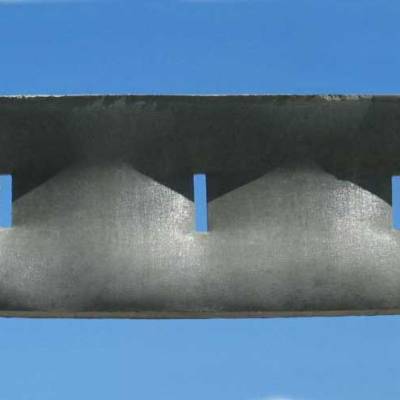

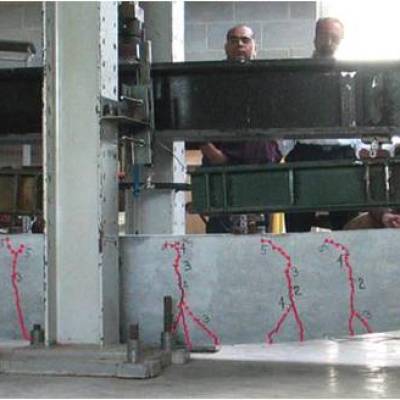

<align justify>C.A.S.T. students explore full-scale construction techniques by first modeling them in plaster (Figures 1 - 4) and then casting them in concrete at full-scale (Figures 5 - 13). And as part of the engineering research being done at C.A.S.T. Ph.D. students are conducting structural tests on variable section beams and trusses as well (Figures 14 and 15). Variable section beams in general and the ‘pinch’ beam in particular (Figure 8), by using one-third the concrete of an equivalent rectangular beam, can offer a substantial savings in the amount of materials required for construction contributing to a more efficient and sustainable design.</align>

<align justify>Simple, flat rectangular sheets of fabric are also being used to explore the shapes columns might take (Figures 16 - 20). And while structural efficiency may not play a major role in their design their appearance is anything but boring as they can take on a very sculptural look (Figure 21).</align>

<align justify>Most recently C.A.S.T. research has focused on thin-shell concrete vaults formed from fabric molds. These vaults can themselves serve as molds for stay-in-place formwork pans or glass fiber reinforced concrete (GFRC) applications. Their innovative work closely follows methods of funicular shell formation first pioneered by Heinz Isler. Isler used small scale funicular models to determine full-scale geometry and structural behavior of reinforced concrete thin-shell structures.</align>

<align justify>Fabric sheets are allowed to deflect into naturally occurring funicular geometries, producing molds for lightweight funicular compression vaults and double curvature wall panels. Figures 22 thru 25 show the process of taking that pure funicular tension geometry and inverting it to produce pure funicular compression geometry, a most efficient structural shape. And, as a method of construction, inverse casts can also reduce the amount of concrete used and as a result the dead weight superimposed on the supporting structural members below. It should be noted here however, that in order for the compression vault to carry a uniform load the fabric formwork membrane must also be loaded uniformly. Other loading conditions can be accommodated by altering the load placed on the membrane to reflect the design load which automatically alters the membrane’s geometry accordingly.</align>

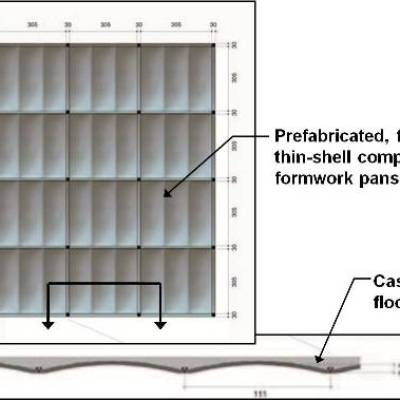

<align justify>Creating formwork intended for thin-shell GFRC stay-in-place formwork pans for CIP floor slabs or thin-shell funicular compression vaults also shows great promise. Figures 26 thru 29 show the process of creating the prototype funicular fabric-formed mold. The use of GFRC stay-in-place formwork pans for a CIP floor slab system shown in Figure 30 allows the slab to span between integral support beams in pure compression. The reduction of construction materials including those consumed in formwork, concrete and reinforcement along with a reduction in the deadweight of the system all help to contribute to structural sustainability.</align>

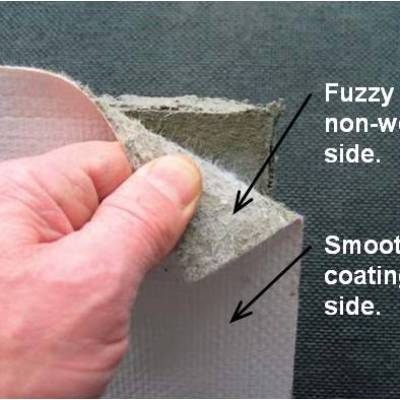

<align justify>Fabric-formed rigid molds required the production of a new fabric that allowed concrete to adhere to one side but not the other. High density fabrics woven from polyethylene or polypropylene can be manufactured with a smooth coating on one side and a fuzzy non woven fabric welded to the other. Concrete placed against the smooth coated side will release without the use of release agents but adhere to the fuzzy non woven side (Figure 31).</align>

<align justify>Another vault option being explored is a direct-cast fabric-formed thin-shell vault that can span between abutments in a beamlike fashion. These members are formed using a single flat rectangular sheet of fabric simply hung from a perimeter frame and used as a mold to form a double curvature vault. Figures 32 thru 35 show the process of creating double curvature funicular thin-shell vault shape. Using a carbon fiber grid in lieu of conventional reinforcing steel allows for a creation of a very thin section – only 3cm (1.2 in.) thick (Figure 36). Figures 37 thru 40 show the process of creating double curvature lenticular thin-shell vault shape. The completed vaults, as shown in Figures 36 and 41, would certainly enhance the appearance of any enclosed space. C.A.S.T. has created a number of variations in vault construction using this fabric formed approach; see their website for further information.</align>

<align justify>Another approach to forming thin-shell panels from sheets of fabric is to hang them and spray them with GFRC. The double curvature shapes a hanging sheet takes will naturally provide stiffness and strength to a thin concrete shell panel (Figures 42 - 46). Again, GFRC may be the best material choice as the random fiber reinforcing can give the concrete the flexural strength and ductility needed to resist superimposed loads.</align>

<align justify>The engineering of these complex and exotic vault and thin-shell panel shapes will require an approach different than the form-finding approach described above for a horizontal fabric formed precast panel. Whereas Isler tested small scale models of his shell structures and then scaled them up to full size these vaults and thin-shell wall panels may already be at full-scale before they are put to use. Two approaches to the engineering analysis of these thin-shell panel shapes might be considered. One is a photographic method using a commercially available software program called PhotoModeler® Scanner [7]. This program imports images from a digital camera to create a dense point cloud and mesh data which can be exported to FEA software. Another method might be to use High Definition Laser Scanning which also creates a dense point cloud and mesh data which can be exported to FEA software. Both approaches will involve an iterative process where one would first image the basic member shape and then analyze it for the superimposed design loads. Results of the first analysis would show where weak points in the member occur. Further analysis would suggest to what degree the member needs to be built-up using additional textile reinforcement and concrete materials.</align>

Conclusions and Further Research

By utilizing a flexible fabric formwork, such as a geotextile, several advantages have been noted:

- The forming of very complex shapes.

- Geotextile fabric is strong, lightweight, inexpensive and is reusable.

- Improved surface finish and durability – due to its filtering action.

- A more efficient and sustainable design is possible since material is placed only where it is needed ― “form follows function”.

- Flexible fabric formwork increases freedom of design expression and can spark the imagination of architects and designers to think beyond the simple prismatic shape.

- The development of a fabric formwork system has the potential to significantly reduce man’s impact on the environment in terms of materials and energy usage.

The advancement of FABRIC-FORMED concrete would be furthered by:

- Design and modeling verification for research work being done on precast concrete wall panels is needed.

- Investigating reinforcement options:

- Fiberglass rebar

- Alkali resistant (AR) glass textile

- Carbon-fiber grids

- The development of new fabrics, with improved properties over those of geotextile fabrics, for use as flexible formworks.

- The development of standards and guidelines for use in precast and cast-in-place forming systems are needed for this method of forming to be of practical use to the design community.

<align justify>We hope this article has piqued your interest and left you inspired. Readers interested in additional information are encouraged to visit the websites listed under Further information especially, the C.A.S.T. website at the University of Manitoba where numerous examples and literature on this topic may be found.</align>

Research Papers

<align justify>This map from the ISOFF website shows you where in the world papers by people interested in this unique forming method are being written. Click on a place on the map or a place in the table to view the paper(s). <fc #FF0000>NOTE!! PAPER LINKS ARE MISSING AS OF 9/25/2015</fc></align>

<align center></align>

References

[1] West, M., (October 2003), “Fabric Formed Concrete Members”, Concrete International Vol. 25(10), pp 55-60.

[2] West, M., (April 2002), “Prestressed Fabric Formworks for Precast Concrete Panels”, Materials Technology Workshop, Department of Architecture, University of Manitoba, Canada., Web address: http://www.umanitoba.ca/cast_building/resources.html

[3] West, M., (April 2004), “Prestressed Fabric Formwork for Precast Concrete Panels”, Concrete International Vol. 26(4), pp. 60-62.

[4] Schmitz, R., (2004), “Fabric Formed Concrete Panel Design” Master’s thesis, Milwaukee School of Engineering, Milwaukee, Wisconsin 53202.

[5] Schmitz, R., (2006), “Fabric Formed Concrete Panel Design”, Proceedings of the 17th Analysis and Computation Specialty Conference on the 2006 Structures Congress CDROM published by ASCE, ISBN 0-7844-0878-5.

[6] ADINA R & D, Inc. ADINA (Version 8.5). [Computer program]. Available: ADINA R & D, Inc., 71 Elton Avenue, Watertown, Massachusetts 02472. September 2008.

[7] EOS Systems, Inc. PhotoModeler® Scanner (Version 6.3.3). [Computer program]. Available: EOS Systems, Inc., 210-1847 West Broadway, Vancouver BC V6J IY6 Canada. April 22, 2009.